A Few Most Common PCB Assembly Methods

This article discusses some of the most common PCB assembly methods available. Let’s get started.

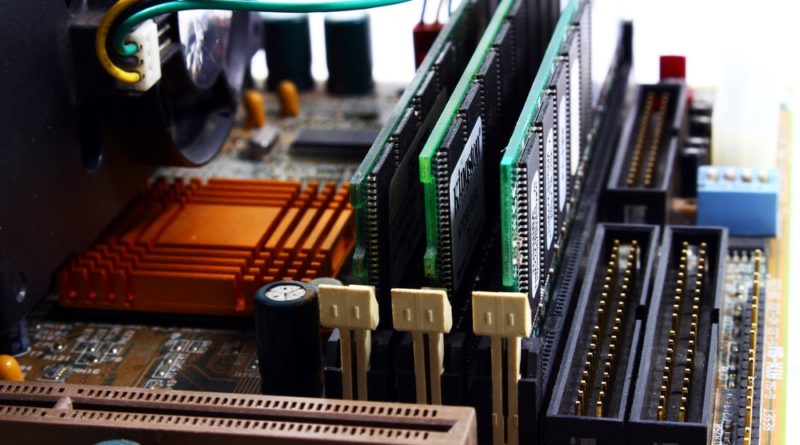

A printed circuit or PCB is basically a device and its key function is to connect electronic parts like transistors, batteries, resistors, etc. in electrical devices and machines. It connects electronic parts utilizing conductive pathways carved from copper sheets that are laminated onto an insulating substrate.

If you have a look around your home, you are surrounded by printed circuit boards. All domestic and commercial electronic machines and equipment have PCBs fitted in them, be it computers, air conditioners, dishwashers, Televisions, and more. Manufacturing PCBs at a commercial level isn’t easy as there are many technical nuisances involved in it.

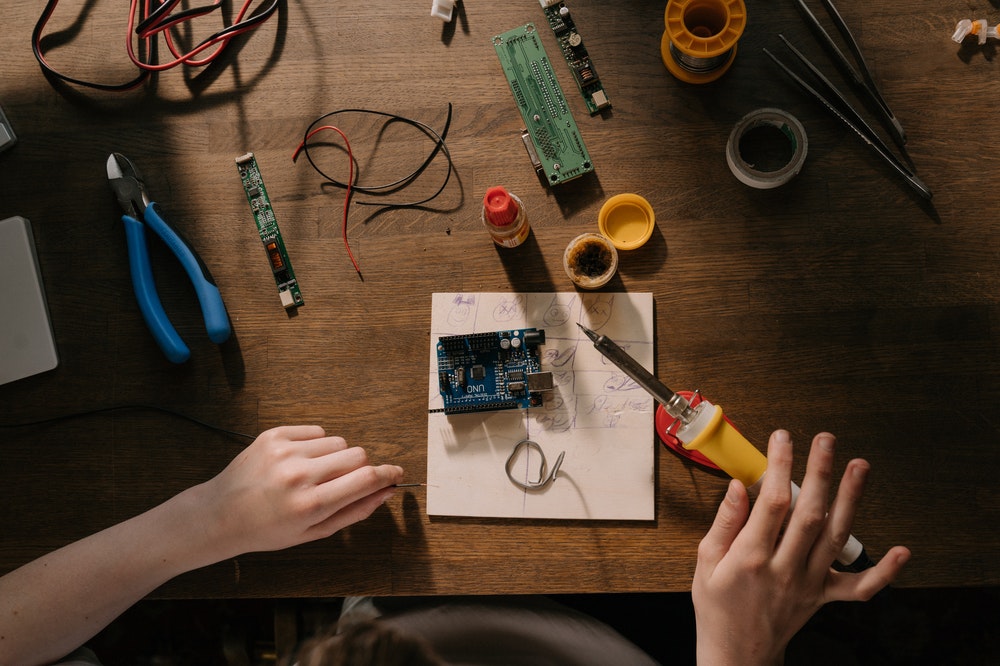

When it comes to PCB assemblywhich we are going to focus on in this write-up, there are many methods used in the industry. Some of the most popular methods are mentioned below:

Surface Mount Technique

SMT or Surface Mount Technique has come out in the market in the 1960s and has become hugely popular from the late 1980s. Electronic parts like resistors, transistors, etc. have metal tabs on them that could be attached to the board through soldering. Higher circuit densities become viable today as modern boards can have components on both sides of the circuit board.

SMT technique is very common when there is a need to create compact size and light in weight electronic products. This PCB assembly method allows electronic elements to be closely knit together.

It is a cost effective method and offers greater design flexibility. Another benefit of this method is the quicker production of PCBs. In this assembly process, no drilling of circuit boards is needed. It saves precious time of the production run.

A lot of business owners and assembly service providers prefer this method around the world in view of the fact that SMT connections are quicker to make and call for less labor as compared to other available assembly processes.

SMT offers a higher level of client satisfaction as it leads to simpler circuitry making it specifically beneficial in complex circuits. The automation used in this process saves a lot of time and dollars for the customers. It offers shorter lead times that provides business owners with a competitive edge over their competitors.

TH or through hole technology

It is an assembly process that turns in the late 1940s. It replaces point to point technology. This PCB assembly technique provides more mechanical strength. It includes drilling holes in a board wherein electronic elements are attached to the board. This leads to more robust connections; however, it is a conventional technique, which is time and labor intensive in view of a lot of drilling work.

SMT is the most popular technique nowadays; nevertheless, TH assembly has its own place in the market. It offers more robust and reliable connections as compared to any other assembly technology.

TH assembly is still the first choice for making electronic products that have to undergo high voltage and mechanical stress. A few of the most common electronic products that involve TH assembly are transformers, semi conductors, etc.

Further, aerospace and military applications always prefer TH assembly as the products made via this assembly can deal with higher temperatures as well as accelerations.

Other PCB assembly methods include box build technology. In this technology, assembly providers make use of cable assemblies, wire harnesses, and more to produce printed circuit boards.

If you are searching for a printed circuit board assembly provider in your area, you can search on any search engine like Google or Yahoo. Today, in the time of globalization, you can also outsource your PCB assembly needs to any provider in the world. You will find plenty of choices on the web.